FLAT PANEL PENDULUM MOTION BUCKY SYSTEMS

Imaging excellence from the name you trust!

The Pendulum Motion Advantage…

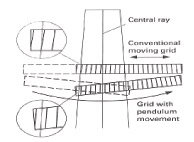

- Anti-scatter grid with Variable Pendulum Motion keeps grid lamellae 100% parallel to the X-Ray beam

- Potentially lower dose imaging depending on the techniques being used

- High remnant beam transmission for even density and shorter exposure times

- Line-free imaging with exposures as short as 10 mSec

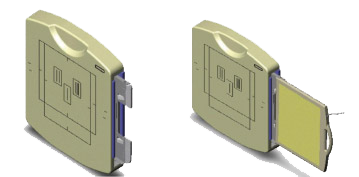

Claymount integrated Table and Wall Bucky Systems provide a cost-effective solution for digital imaging – grid, solid-state measuring chamber and flat panel all in a single space-efficient enclosure. Designs available for many Flat Panel Detectors including:

Pixium© 4600

Varian PaxScan© 4343R

XMARU© 1717

FLAATZ© 750

Pixium© 3543pR Varian PaxScan© 4336R XMARU© 1417 FLAATZ© 550

Optional Manual or Automatic rotation available for Portrait/Landscape orientation Designs for other detectors are also available.

Claymount is also a specialist in stationary-grid Docking Stations For Canon© CXDI 50C/50G and CXDI 55C/55G

FLAT PANEL PENDULUM MOTION BUCKY SYSTEMS

|

Popular Fiber Interspaced Grid Configurations other choices available – consult Claymount |

|||

| Focal Distance (cm) | Lines/Inch | Grid Ratio | Bucky Factor |

| 110 | 36 | 10 | 5.0 |

| 44 | 10 | 4.7 | |

| 120 | 36 | 10 | 5.0 |

| 44 | 10 | 4.7 | |

| 140 | 36 | 10 | 5.0 |

| 12 | 5.5 | ||

| 44 | 8 | 4.7 | |

| 10 | 4.7 | ||

| 12 | 5.2 | ||

| 80 | 15 | 5.4 | |

| 180 | 36 | 10 | 5.0 |

| 12 | 5.5 | ||

| 44 | 10 | 4.7 | |

| 12 | 5.2 | ||

The Claymount Pendulum Motion Bucky features our precision-controlled Variable Speed Drive Technology. Operating with the on-board software, the grid rapidly accelerates to its highest speed following synchronization contact and prior to emission. This ensures that the grid moves through its entire arc of travel during exposure which helps provide high contrast line-free images at a potentially lower dose. Each grid is fitted with encoder tabs that allow the control to detect the focal distance, ratio and line count of the grid, and optimize the Pendulum motion profile during exposure.

Claymount Assemblies B.V.

Anholtseweg 44, 7091 HB Dinxperlo

P.O. Box 44, 7090 AA Dinxperlo

The Netherlands

T + 31 (0) 315 659 150

F + 31 (0) 315 659 140

nl.office@claymount.com

Claymount Assemblies Philippines Inc.

Buildings 9, 10 & 11 Harvard Avenue

EZP Business Park

Calamba Premiere International Park

Special Economic Zone

Batino, Calamba City

4027 Laguna, Philippines

T + 63 49 502 4520

T + 63 49 502 4521

F + 63 49 502 4500

ph.office@claymount.com

Claymount Italy

Via Lirone, 60c

40013 Castel Maggiore - Bologna

Italy

T + 39 051 632 01 23

F + 39 051 632 25 48

it.office@claymount.com

Claymount High Voltage Technology (Beijing) Co., Ltd.

Kang Sheng Industrial Park

Building # 2, 11 Kang Ding Street

Beijing Economic & Technological Development Area

Beijing 100176, China

T + 86 10 6780 2708

T + 86 10 6780 2129

F + 86 10 6780 2966

cn.office@claymount.com

Claymount North America Corp.

960 Industrial Drive, unit 3

Elmhurst IL 60126

U.S.A

T + 1 630 833 2030

T + 1 630 833 2157

us.office@claymount.com

Illustrations, specifications and

technical data are subject to change without

notice. Some features described in this

document may be optional.

Owner/Rev. ENOV/jan2011 dcn01